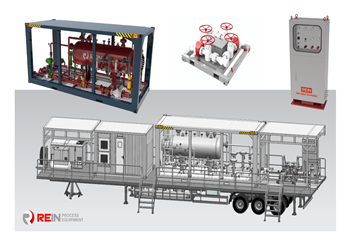

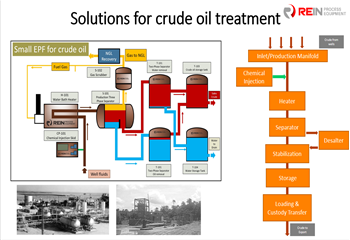

Rein Process Equipment is an engineering and manufacturing company from China that designs and supplies process equipment for Early Production Facilities. At this moment, our company is actively participating in new project in Middle East for new oilfield which shall be produce high viscosity crude by the end of 2021. Our company is estimating the value, preparing PFD and P&IDs for new oil & gas project.

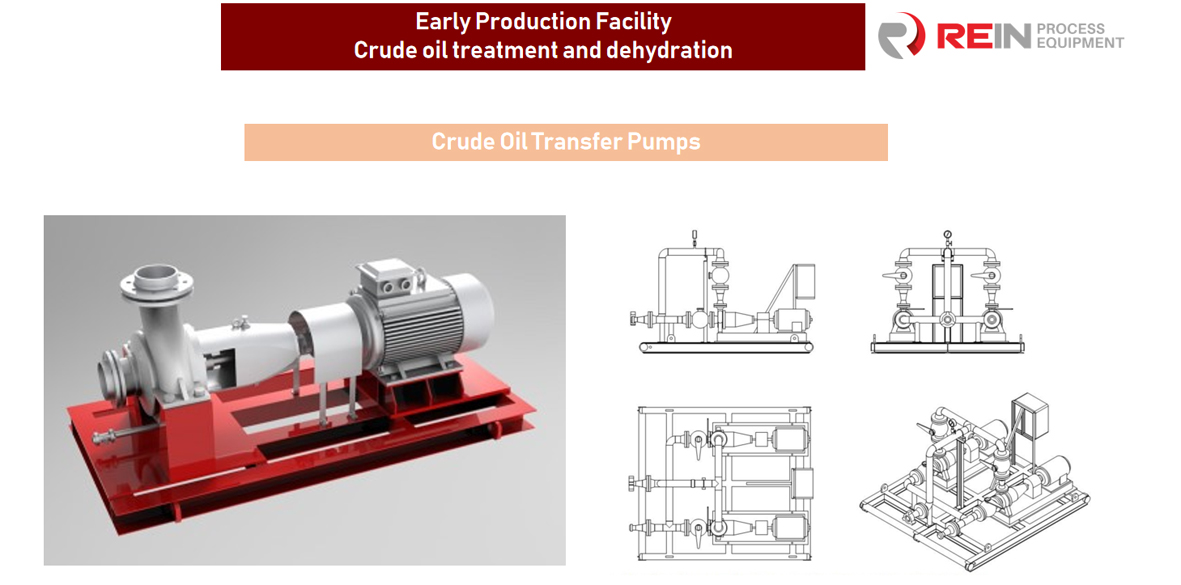

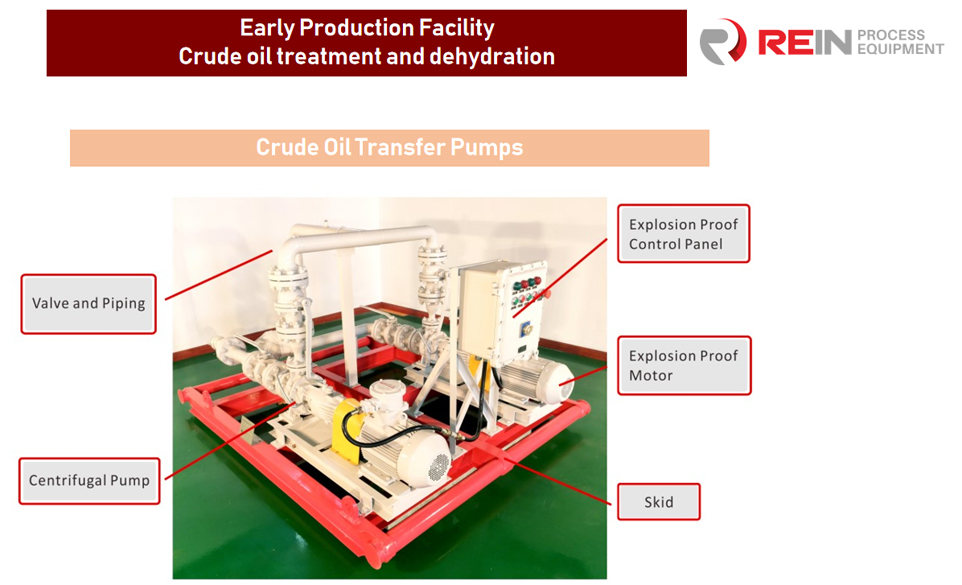

Early Production Facility will treat and produce export oil with requirements to BS&W of 0.2-0.5%. EPF’s capacity is 10000 BOPD. Rein’s Scope of work for this project includes design, engineering, FEED development, PFD development, P&ID development, mechanical engineering, electrical engineering, piping engineering, equipment civil engineering works, fabrication, test and assembly of static equipment, such as High-pressure and low-pressure production separators, heater treaters, crude oil heaters, surge tanks, degasser boots. Also, Rein will design and supply rotating equipment, such as chemical injection pumps and skids, crude oil transfer pumps, etc. Rein also will supply automation and control system which allow to operate facility from control room remotely or by operating with local control panel.

Inlet Section and Chemical Injection

Inlet Section of EPF facility will consists of inlet manifold or MSV manifold, which has 10 entry ports, chemical injection ports, ESD Valve and system, as well as other systems allowing to protect pipeline and maintenance. Chemical, such as demulsifier, corrosion inhibitor, and other chemicals are necessary to increase separation efficiency and prevent pipeline and process equipment from corrosion and fouling.

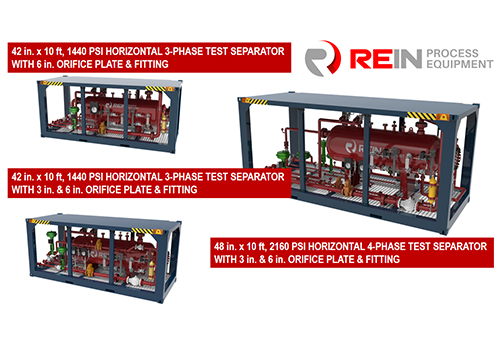

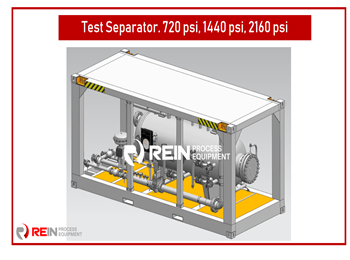

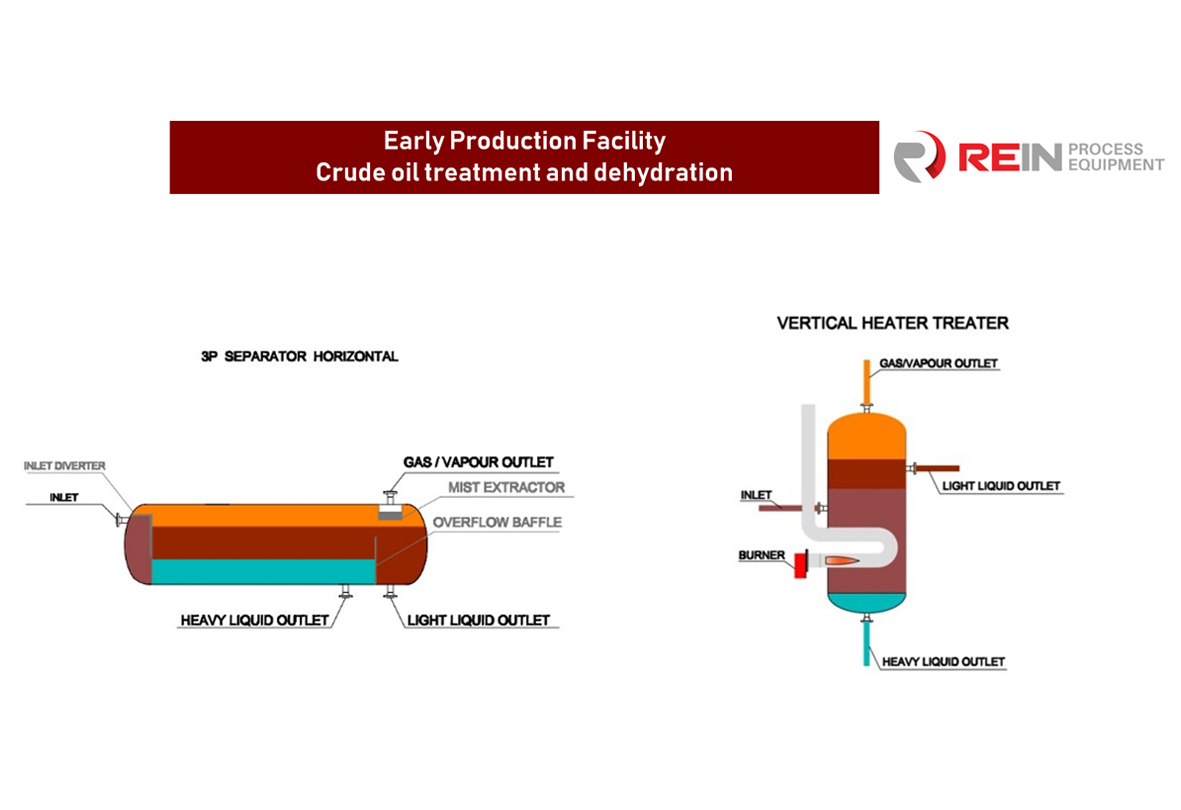

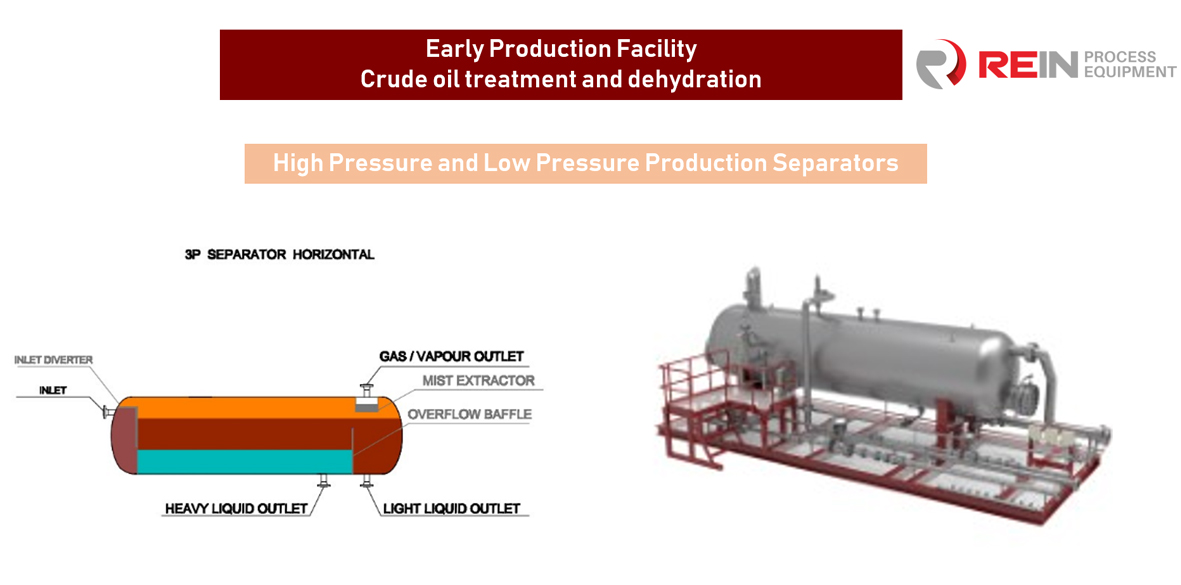

Separation Section

High-pressure and low-pressure production separator will be provided for bulk separation of oil, free-gas and water. Production separators will be equipped with level controllers and control valves to discharge light and heavy liquids when it reaches certain point. ESD system will monitor level, pressure, and temperature in production separators to shut-down process line during emergency.

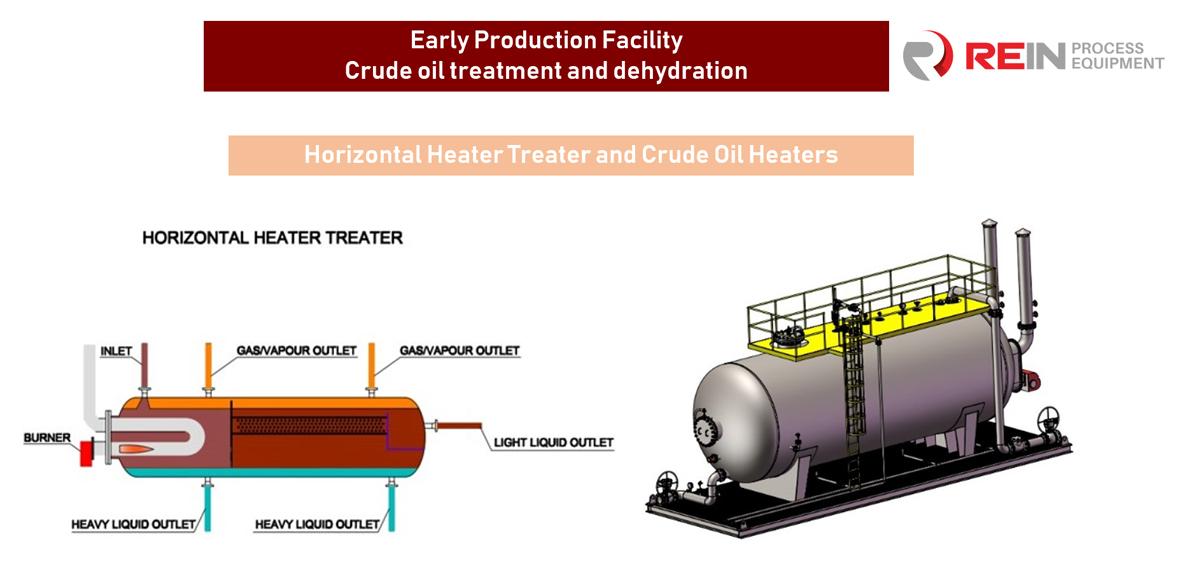

Heat-treatment

Heater Treaters will be installed in separator upstream allowing additional separation of liquid and gases. Heat Treatment is widely applied technology of crude oil treatment. Crude oil heater by burner which heats fire tubes that transfer heat to the crude oil, increasing its temperature.

Electrostatic Treatment

Electrostatic Treatment Section of EPF consists of electrostatic dehydrator and electrostatic desalters, which allow operator to reach specification of export crude oil, which is BS&W 0.2-0.5. Also, salts will be removed in section stage (desalting) and salt level will be reduced to required level.

Storage and Transport

Storage of spec. crude oil will be conducted by API storage tanks, which will be designed to keep up to 10000 m3 of crude oil. Storage tank will be equipped with electric heater to maintain temperature of the oil. Transportation will require loading arms and metering units. Loading arm will load crude oil trucks will liquids, while metering skid will measure how much oil is exported.

Utility Systems

Utility systems which consist of power-supply, steam-supply, instrument air-supply will be supplied in cooperation with local contracting company to ensure proper integration during construction stage.