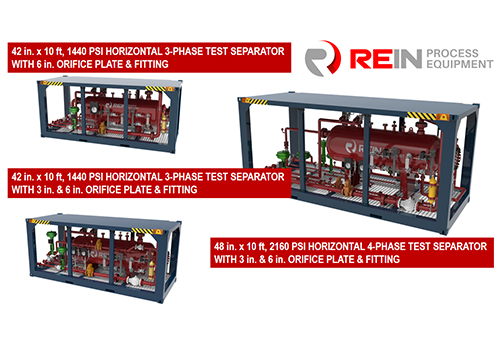

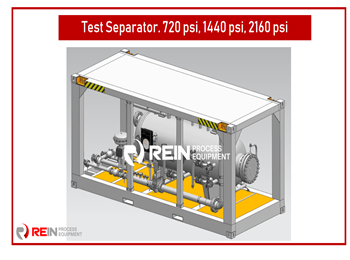

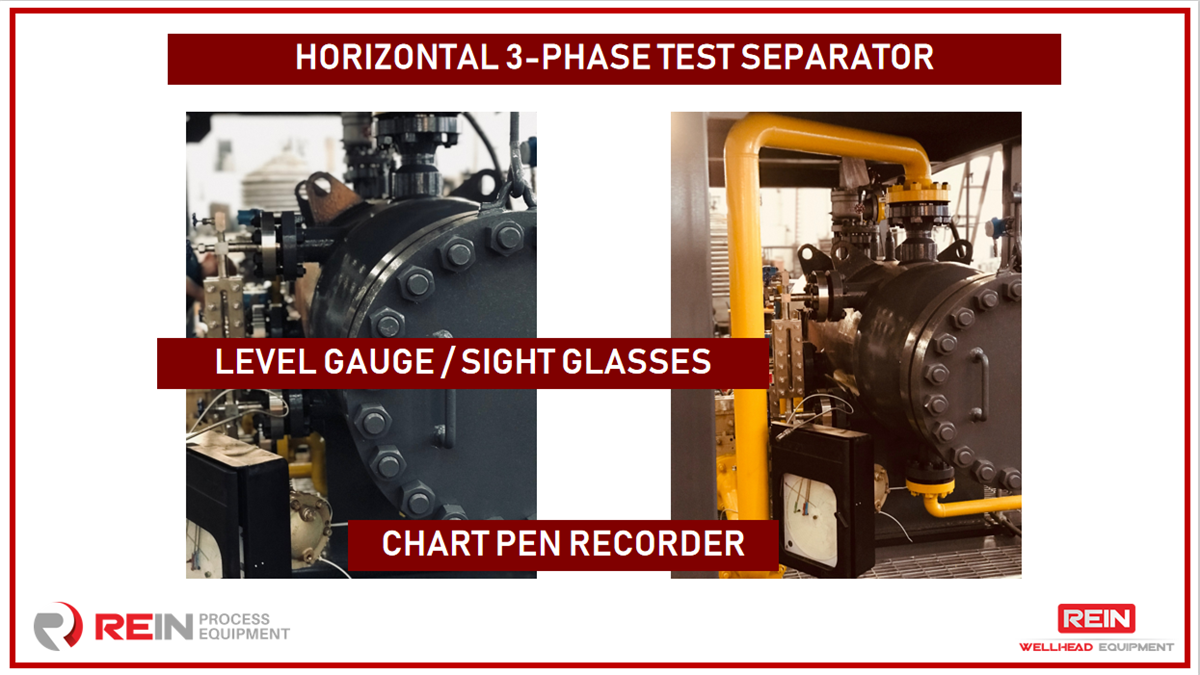

Surface Well Testing is a very important process of oil & gas well development and production. Surface well testing requires sets of equipment for obtaining precise data concerning well flow and properties of valuable hydrocarbons. Test Separators are one of the most sophisticated and important equipment for flowback and well test operations. Test Separator shall have durable components, high-quality instruments, such as level gauges, level controllers, gas flowmeters, pressure and temperature recording equipment, as well as flow-control and safety equipment.

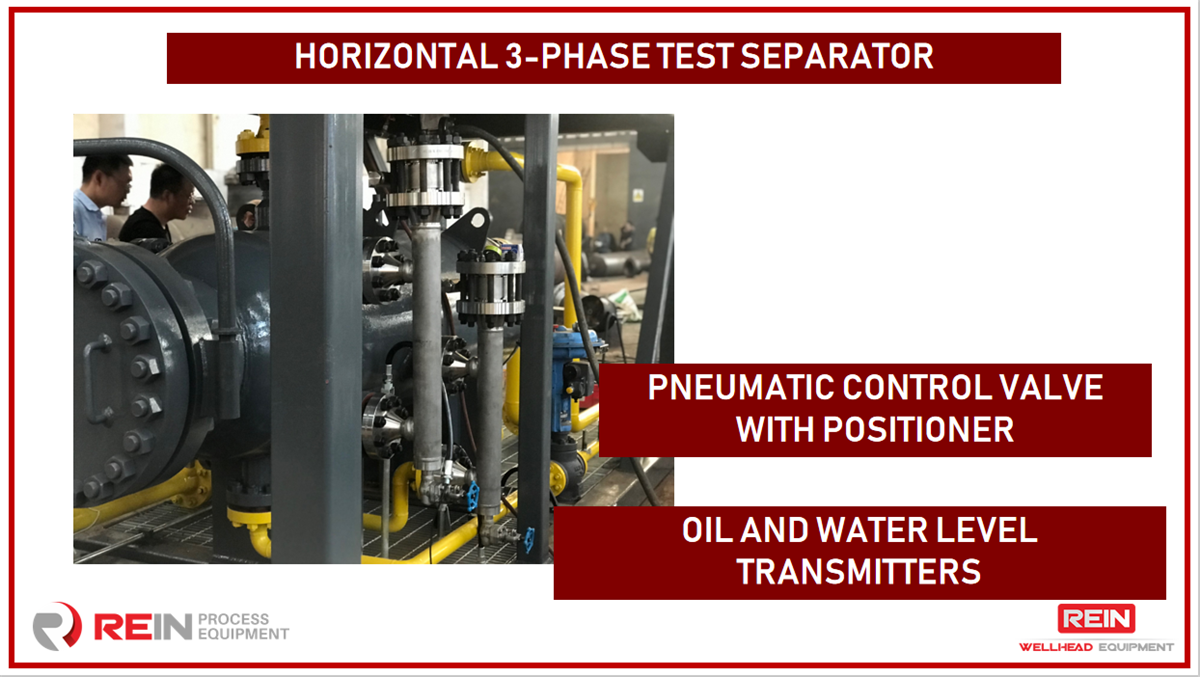

Some oilfield service companies prefer to use remote digital liquid control for oil and gas. Level Transmitter sends a signal to PID controller, which sends signal to the positioner of pneumatic control valve, which controls flow automatically. Before starting operation on test separators, well test operator shall check calibration and functioning of all instruments. Separator manufacturer also shall calibrate separator and its instruments before shipment.

For test separator calibration, often atmospheric gauge tank or vertical surge tank is used. In case of H2S and other acid gases present in reservoir, test separators, as well as other surface well test equipment shall be made of sour-service materials and comply to local or international standards.

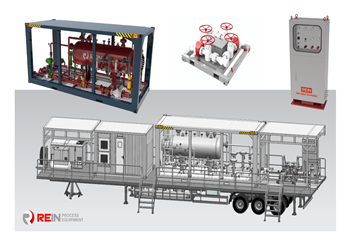

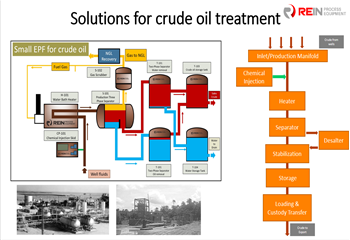

Rein Process Equipment is an engineering and manufacturing company, which supplies wide range of surface well test equipment, flowback equipment, as well as EPF packages for domestic and international markets. Feel free to contact Rein for technical assistance and quotation for oilfield equipment.