Alkylation is a reaction in which alkyl (methyl, ethyl, etc.) is introduced into the molecule of a compound. In a standard refining process, the alkylation system, under the action of a catalyst (sulfonic acid or hydrofluoric acid), combines low molecular alkenes (mainly composed of propylene and butylene) with isobutane to form alkylates (mainly composed of higher octane and side-chain alkanes).Alkylate is a gasoline additive that has antiknock and produces a clean product after burning.

Liquid phase alkylation can be carried out in horizontal or tower reactors, and reaction heat can be removed by cooling pipes or evaporative refrigeration in the reactors. The alkylation process can be divided into two kinds: hydrofluoric acid alkylation and sulfuric acid alkylation according to the different catalysts used. As the catalyst is corrosive, the reactor must be manufactured or lined with corrosion-resistant materials. In order to ensure sufficient mixing of reactants and acids and to control a certain residence time, stirring, circulation, baffle or multistage tandem reactor can be used.

Reactor is a kind of equipment to realize the reaction process, which is widely used in the fields of chemical industry, oil refining and metallurgy. The device is always equipped with stirring device (mechanical stirring, air stirring, etc.). In case of large Height-Diameter ratio reactor, a multilayer agitator may be used. Most reactions have significant thermal effects. In order to make the reaction be under the appropriate temperature conditions, the heat exchanging structures are usually set up on the reactor, for example, the reactor wall jacket, internal heat exchanging surfaces, or external circulation pipes.

Reactor plays an important role in process industry. In terms of the construction investment and operation cost of the whole process, the proportion of reactors may not be very large. However, its performance and operation have an impact on the post-treatment and post-treatment as well as the production and quality of the product, and also on the consumption of raw materials, energy consumption and product cost. Therefore, the research and development of reactors is of great significance to the development of various process industries.

A reactor is a pressure vessel that is often operated under atmospheric pressure, pressure, or negative pressure (vacuum). Its manufacture and design must conform to the local national or international standard of pressure vessel manufacturing. The types of commonly used reactors contains: the tubular reactor, the tank reactor, the solid bed reactor, the tower reactor, the jet reactor and others.

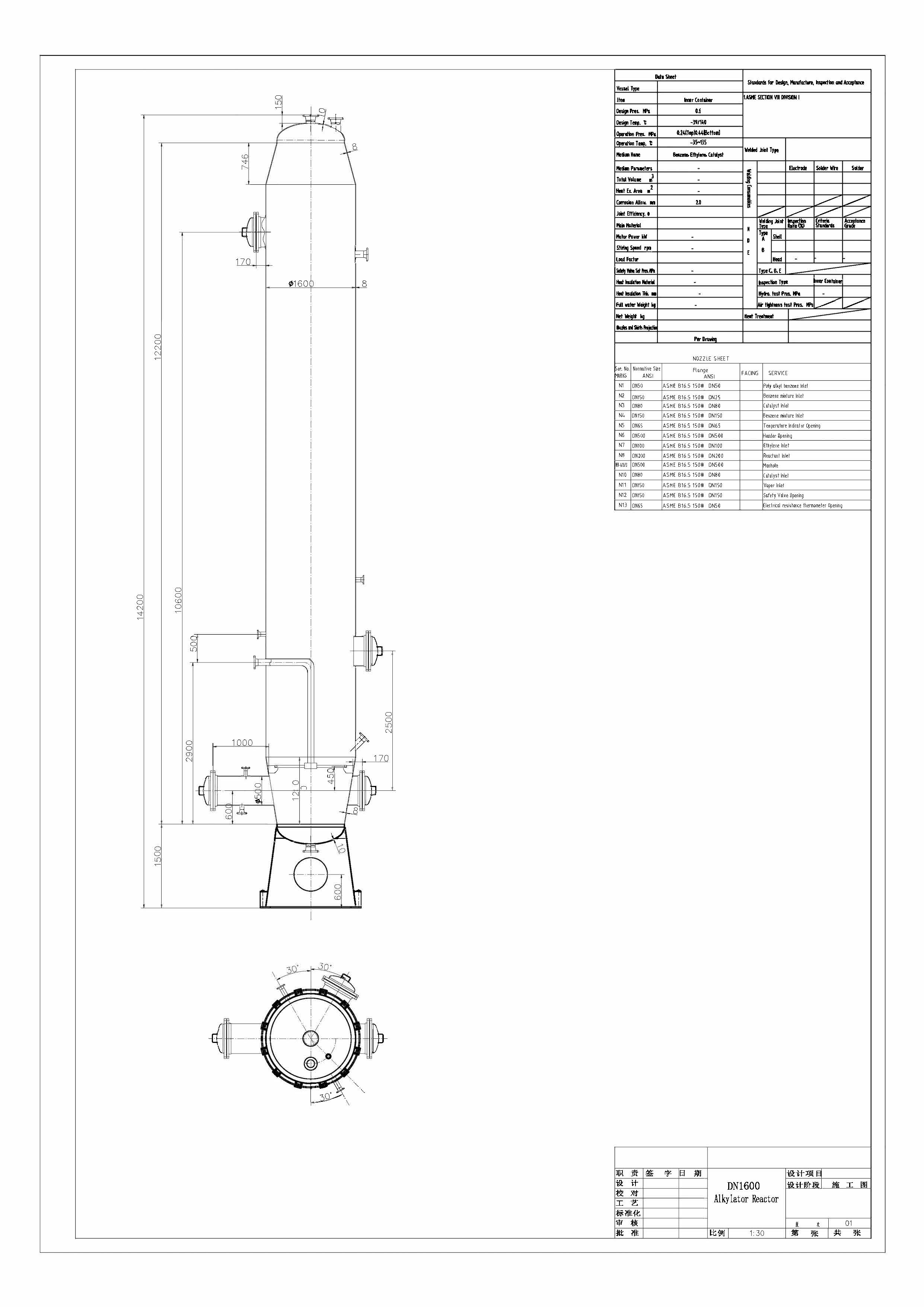

(The pictures are only for reference. Your required equipment appearance depends on detail designing)