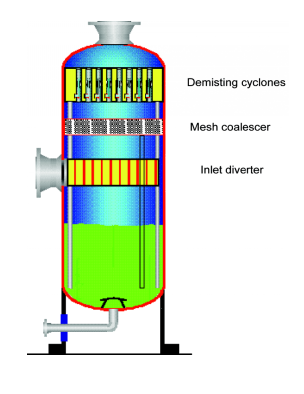

This unit has a high turndown capacity (that is, the ability to operate effectively at much less than the design capacity) and a small droplet capture range. The inlet diverter removes bulk liquids. At low rates, the mesh pad acts as a separator and removes the mist. At higher gas rates, the mesh acts as an agglomerator, coalescing small drops into larger ones. The larger drops are re-entrained but caught by the cyclone demisters. Typical turndown is ~8 to 10.

A scrubber is a two-phase separator that is designed to recover liquids carried over from the gas outlets of production separators or to catch liquids condensed due to cooling or pressure drops. Liquid loading in a scrubber is much lower than that in a separator. Typical applications include: upstream of mechanical equipment such as compressors that could be damaged, destroyed or rendered ineffective by free liquid; downstream of equipment that can cause liquids to condense from a gas stream (such as coolers); upstream of gas dehydration equipment that would lose efficiency, be damaged, or be destroyed if contaminated with liquid hydrocarbons; and upstream of a vent or flare outlet. Vertical scrubbers are most commonly used. Horizontal scrubbers can be used, but space limitations usually dictate the use of a vertical configuration.

Gas scrubber is a new type of gas cleaning equipment. It is produced on the basis of the air purifier of floatable packing layer, which is widely used in the pretreatment of industrial waste gas purification and dust removal. Because its working principle is similar to scrubbing process, it’s named gas scrubber.

A gas scrubber mainly consists tower body, tray, reboiler and condenser. Since the scrubber is an equipment for rough separation, the number of trays is generally small and the tower is not big. The scrubber is suitable for the separation of mixed gases with a small amount of dust, whose components will not react and the products should be easy to liquefy. Impurities such as dust (also called high boiling materials) are not easy to liquefy or solidify. When the mixed gas is passed into the scrubber the middle part, the liquid component of product exists between the trays, and the gas component is evaporated at the same time, while the impurity cannot be liquefied or solidified. When passing through the trays with liquid, the liquid component of product will be fixed and resulting in scrubbing action.