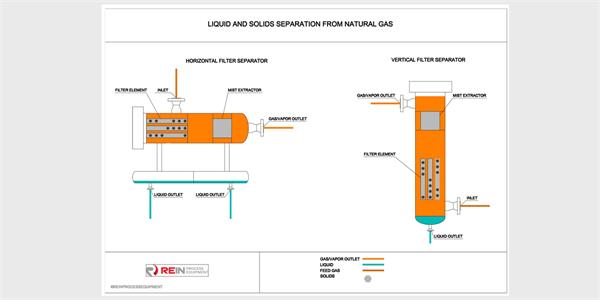

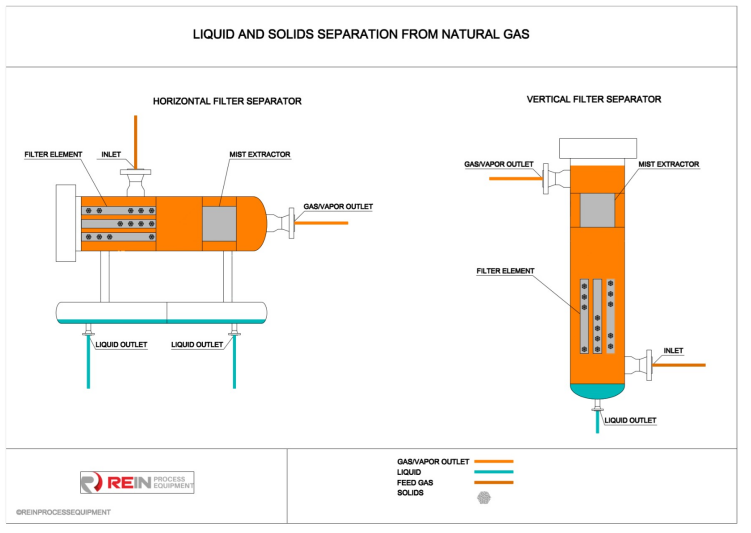

Filter Separator is a mechanical equipment with filtering and separation elements used to remove liquid, small solids (created by the tubing and wing erosion) and other particles from the gas steam.

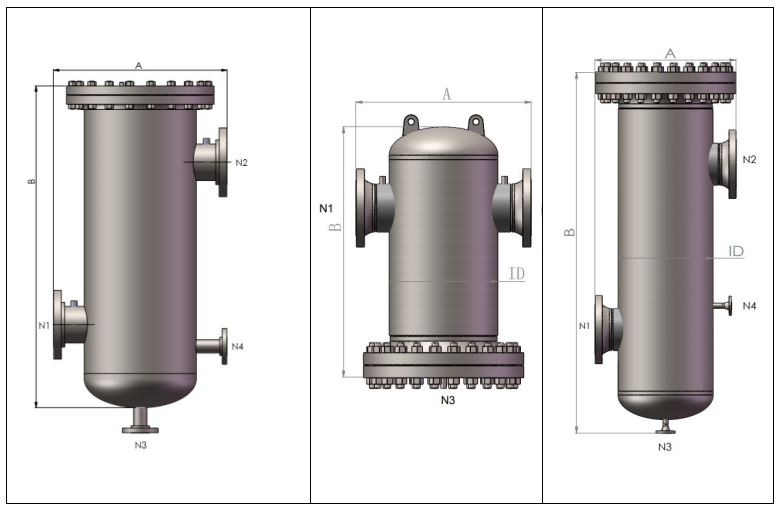

Filter separators, like other gas-liquid separators, can be horizontal and vertical; the most common type is horizontal. If there is a large amount of water in coming gas, structure of filter separator is designed to have a “boot” in the bottom of the separator connected with two similar tubes parallel to each other. Retention period required between 3 and 5 minutes for hydrocarbon (oil)-water separation by settling. Sizing the dimension of the filter separator’s each section depends on the calculations and design of manufacturer or engineering company.

Filter separators have a wide application in gas pipelines, as well as the gas processing plants, for example, acid removal units, when after passing filters separators catch the liquids and condensed hydrocarbons coming from the absorber. In gas processing, adequate inlet separator and filter separator are required to prevent foaming due to the chemical contamination. If absorber is downstream from amine unit, glycol unit, or compressor, a filter separator is required. Also, filter separator and coalescing filter used to prevent fine mists from entering the absorber.

Rein Process Equipment designs and fabricates filter separators in China. Rein Process Equipment is a manufacturer and supplier of quality filter separator with high filtering and separation efficiencies. Feel free to contacts for more information and quotation!

Dimensions | Diameter 4-36 in. Length 8.5-12.5 ft. |

Pressure Rating | 500-1440 psi |

Flow Rate Gas | 9.5-200 MMSCFD |

Filtering Efficiency | 99.5-99.9% |

Vessel Type | Horizontal or Vertical |