Working pressure: 2000-5000Psi

Normial diameter: 2 9/16″-3 1/8″

Temperature grade: LU/PU

Specification grade: PSL1-PSL3

Connection type: Flange/Clamp

Product Standard: API 6A

Temperature rating: -46°C~121°C (LU Grade)

Material class: AA,BB,CC,DD,EE,FF,HH

Product specification level: PSL1-3

Performance level: PR1

Working medium: Water

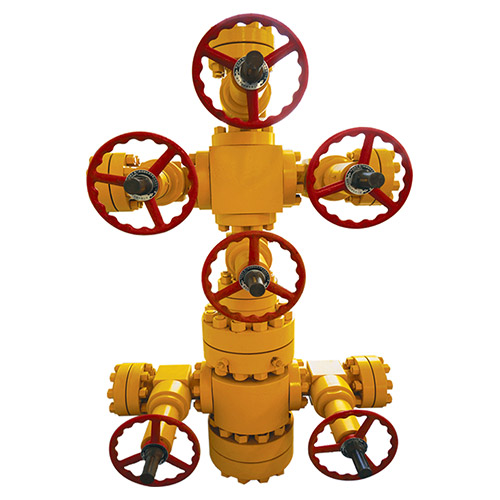

R&T Group’s water injection wellhead meet API 6A standard.

Water Injection Wellhead is mainly included tubing head, gate valve, top flange, cross etc.

Valve can be used based on customer's requirement.

Water Injection Wellhead Design Requirements

Water injection wellhead should be designed in accordance with the following requirements

1. The water injection wellhead should meet the requirements of positive injection, back injection, mixed injection, positive washing, reverse washing, metering oil pressure and casing pressure sampling water.

2. The water injection wellhead needs meet the requirements of well test (such as downhole pressure, temperature, water quantity, downhole sampling, sand surface height and artificial bottom hole).

3. It can also satisfy the requirements of acidification, fracturing, water shutoff, profile control and water absorption profiles.

4. According to the requirements determined by the water wells, the water injection wellhead should have the following characteristics: high strength, long life, work pressure greater than the formation of the rupture pressure, light quality, small size, simple flow, and to minimize the dead water pipe section.

5. The installation of the water injection wellhead: because of different requirements of each oilfield for water injection, the wellhead forms varies in installation. generally there are various types from seven valves to three valves.

Water Injection Wellhead Work Process

According to the characteristics of oil field, water injection technology is divided into concentrated water injection technology and dispersed water injection technology. Centralized water injection technology will be built in the joint or the oil station, outside the station system are high-pressure pipe network, the source water through the distribution valve group to adjust the allocation after the transfer to the water injection wellhead. In the centralized water injection process, the water injection pump has large displacement, small quantity and concentrated construction, with many wells. The water treatment part is built in the dispersed water injection station, the transfer station to the injection station adopts the low pressure water supply, and the injection station adopts high-pressure water injection pipeline to the wellhead from the source water.

Most of the water injection wells in low-permeability reservoirs have large start-up pressure difference. Water injection pressure is high, water injection is difficult to meet the requirements of injection, the result is that the formation energy can not be effectively supplemented, the effect of water injection is not satisfactory. Under the influence of plane heterogeneity, the overall pressurization operation cost is high and the efficiency is low. Through increasing the injection mode of the single well loaded booster pump, the water injection can be effectively improved, and the oil well yield could be increased, so as to improve the flooding efficiency and recovery rate of low permeable oil field.

The water injection station is the core of the water injection system, and the main function is to boost the pressure in the future to meet the requirements of injection well. The main facilities of the water injection station are storage tank, high-pressure pump group, flowmeter, water separator, water distribution room, injection wellhead and so on. Water injection into the ground there are a variety of processes, mainly including the following: single-pipe multi-well water distribution flow, single pipe single well water distribution process, dual-pipe multi-well water distribution flow, partial pressure water injection flow, pressurized water injection flow.